You get the exact specs you pay for. We do not compromise on the Wire Diameter or Mesh Hole. Our tolerances are the smallest in the industry.

You get the most number of wires per sheet. We do not cheat you by reducing the number of wires.

You can request customized specs. We can produce your needs up to your engineer's standard.

If you have concerns with your order’s quality, Viber us a photo or video (0917-797-8824).

If we consider it valid, we will replace it. We will only consider concerns within 10 days of your pickup date though!

Lona: if you bring an open truck, make sure that your pickup truck covers your items with lona to protect from the rain.

Forklifts: use forklifts or cranes to unload /load /transport your items.

Pallets: it’s best to store items on top of pallets. Avoid letting the items touch the ground directly to prevent wet floors from rusting the items.

Roof: it’s mandatory to store items in warehouses with covered roofs.

Rusting: when exposed to air for too long, non-galvanized items like Nails, Wire Mesh, and BI Wire are prone to rusting. Rusting by air only affects the item’s surface, unlike rusting by water. If you plan to store your items for longer than 2 weeks, make sure that the Nail boxes remain sealed, or your Wire Mesh/BI Wire are draped in covers like lona.

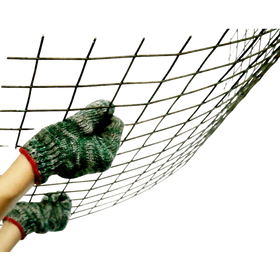

REINFORCE CONRETE WITH OUR DURIAN-BRAND

Wire Mesh

This is also known as Steel Matting. We package them in sheets. Our wires are welded by machines from Singapore. We make the highest standard mesh in the industry.

THE PROCESS: Several lines of BI Wires are fed in parallel and resistance-welded with perpendicularly-placed wires to form the mesh size desired.

USAGE#1

Concrete Slabs & Precast

Wire Mesh is placed on the slab before pouring concrete. Its tensile strength minimizes future cracks in the resulting concrete slabs or precast panels.

Ribbed Wire Mesh can be more effective because the ribbing/deformation of the wires enhances bonding with the concrete. Recommended sizes are those with 4x4” or 6x6” mesh holes.

USAGE#2

Frames

Wire Mesh is welded together with other steel materials (like angle bars or pipes). This produces a frame partition with the mesh acting as the body of the fence.

This usage of Wire Mesh in this type of fencing is usually for low-cost purposes (e.g. public areas, factories, construction sites, farms). Recommended sizes are those with 2x2” mesh holes.

USAGE#3

Cages

Wire Mesh is welded around a steel frame to form an enclosed structure. These frames can be used for keeping animals.

The bigger the wire diameter, the sturdier the cage. Recommended sizes are those with 2x2” mesh holes.

USAGE#4

Canopy

Wire Mesh is placed over the top of public areas near construction sites where debris could fall and cause accidents. Wide nets or screens are placed on top of the Wire Mesh to catch falling debris.

This is usually used in mid-rise and high-rise construction sites. Recommended sizes are those with 2x2” mesh holes.